Dear ladies and gentlemens!

The given page is devoted to our invention:

Which represents disk-shaped duple rotor-reciprocating engine with

a rotating cylinder block (BI-ROTATIVE*) This is

essentially new

scheme of transferring of energy gases

of internal combustion into mechanical energy.

Nothing common with Vankel's rotor engine!!!

*The rotative engine - from the word "rotation", that means

that the cylinder block rotates about the axis (shaft).

*The bi-rotative engine - the engine in which the energy of gases is

transmitted to a cylinder block and on an axis (shaft), that

means that the engine and an axis (shaft) rotate both.

The full version

in a format .doc -839kb

The given scheme was tested by us! Its functionability

and reliability, on the first test sample with a rotating cylinder block, in

which impact loadings are considerably reduced on metal, was checked up.

The engine (bi-rotative)

made under the new scheme, surpasses on power other analogs with a

conventional system of assembly as a minimum in 2 times. The used scheme has

allowed to avoid back-and-forth motion of pistons,

that has considerably lowered shaft loads at the high speed of the engine and

the friction of details is reduced by 50 %.

All this has allowed to increase sharply

characteristics of the power installation (engine) and its capability, to increase efficiency, to

lower metal consumption (power-to-weight ratio) in some times. Profitability is

raised. The engine (bi-rotative) has a

smooth course, a uniform torque. The consecutive order of ignition is 1.2.3.4.

The construction of the power installation (of the

engine) is simple in manufacturing, that allows to reduce

the period of its creation and of the production manufacturing. The used scheme

has allowed to depart from the traditional system of

lubrication, as the rolling-contact bearings were used. The relation of weight

to power, allows to reach it up to 0,3 - 0,2.

The lead preliminary engine (bi-rotative) tests have enabled to ascertain that

fact, that the engine can be ideally used on a VTOL (vertical take-off and

landing) aircraft.

By

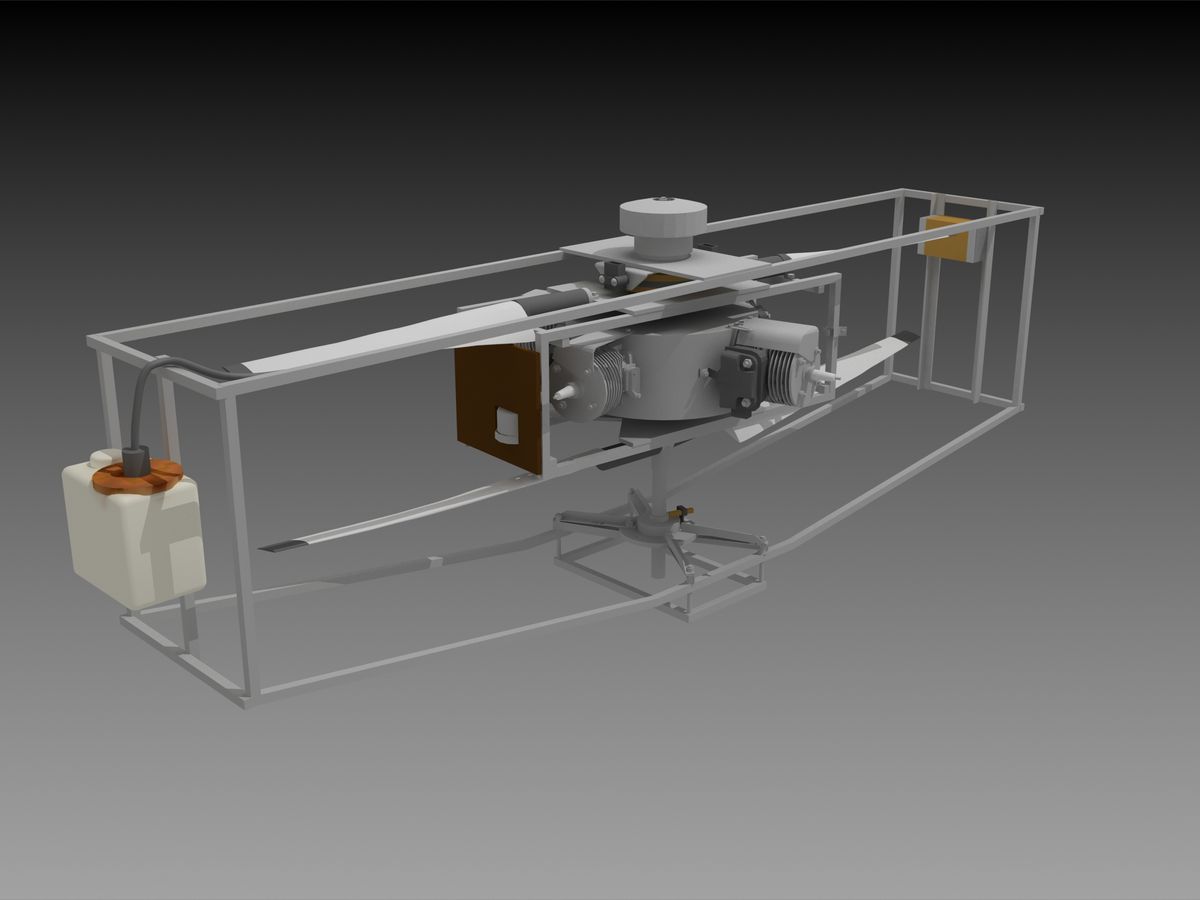

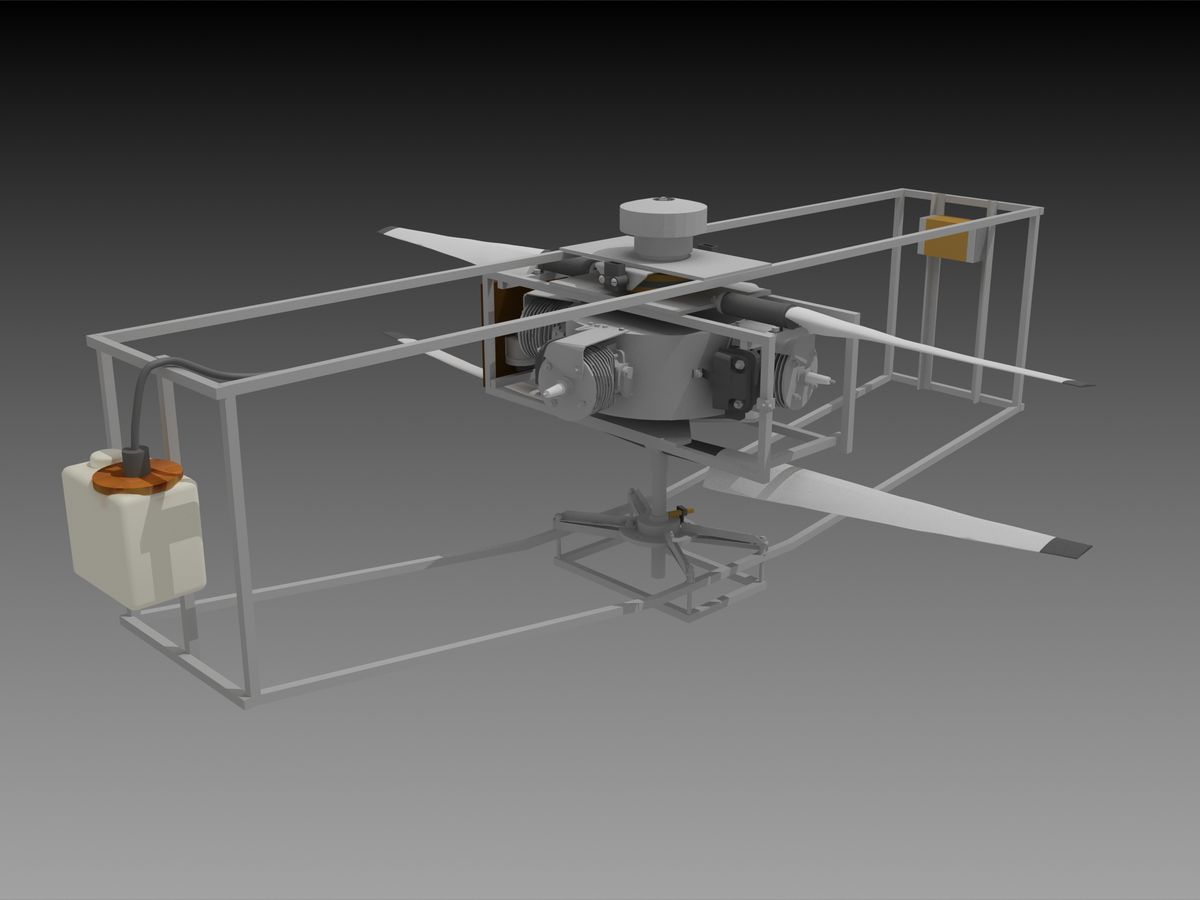

our engineers the demonstrator of the concept of a pilotless VTOL (vertical

take-off and landing) aircraft was designed and made.

Constructional features of the

bi-rotative engine allows

to have two outputs for removal of power

with a different direction of

rotation.

Here in the bottom and from above the propellers are located. The

existing bi-rotative engine allows

to rotate two propellers

in the different sides with identical angular rate that allows to

design flight vehicles under the coaxial scheme, without application of the main

reduction gearbox and a column. Due to it, the weight of a

flight vehicle is essentially reduced and weight of a payload is increased.

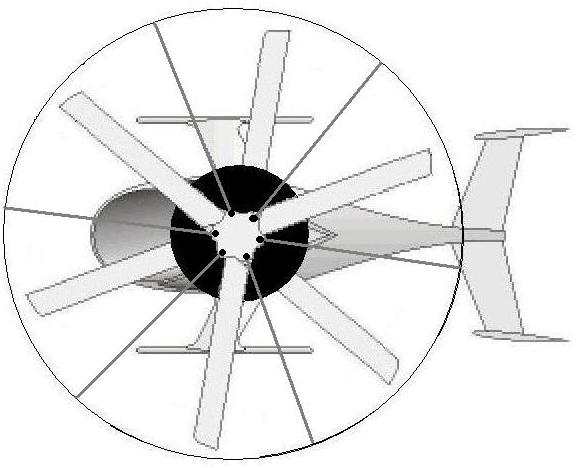

The designed disk-shaped drive (bi-rotative), rotating in a plane, creates a

high-power gyroscopic effect that allows to retain a flight vehicle in the

given plane.

We have a capability to offer the concept of a VTOL (vertical

take-off and the landing) aircraft, based on development by engineers of our

firm. (the scheme №1, №2, №3, №4, №5)

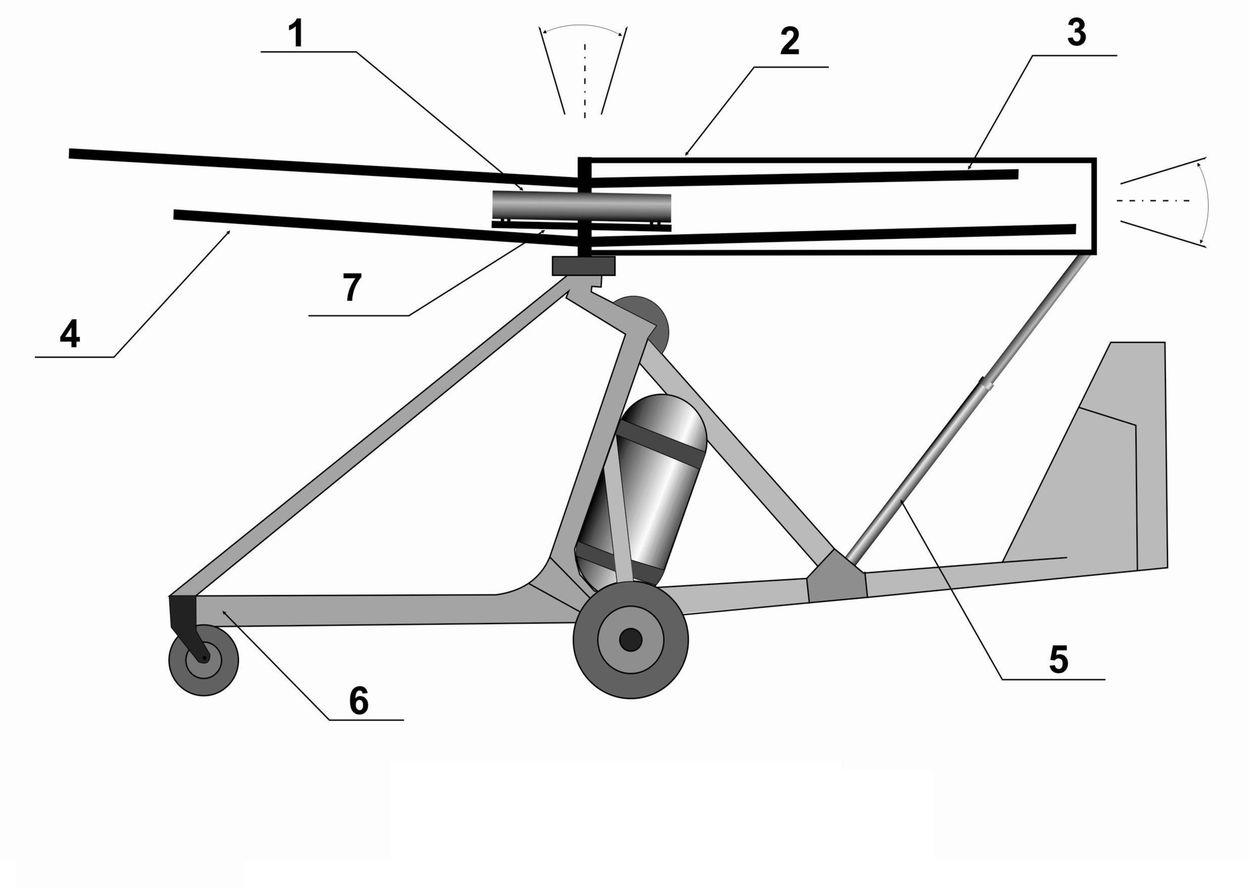

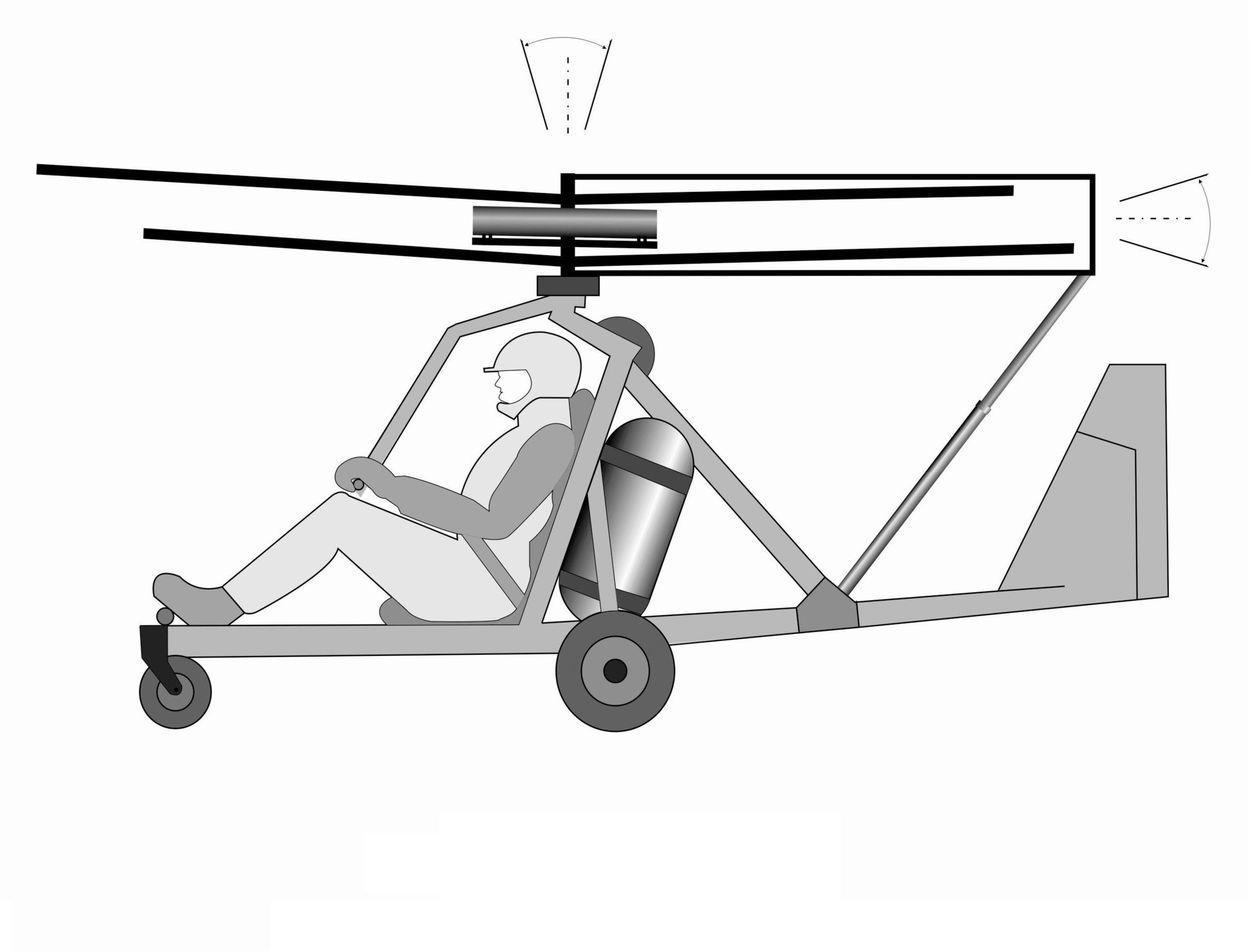

The scheme №1

Unmanned aircraft

1. The disk-shaped bi-rotative engine

2. An engine mount

3. The upper propeller

4. The lower propeller

5. The telescopic rack

6. A carrier frame

7. Exhaust system

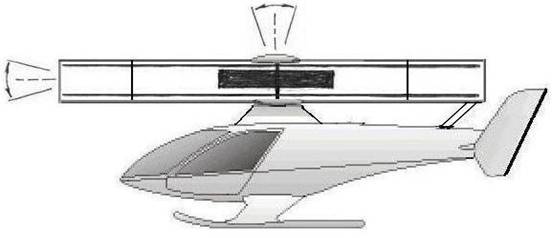

The scheme №2

The scheme №3

The scheme №4

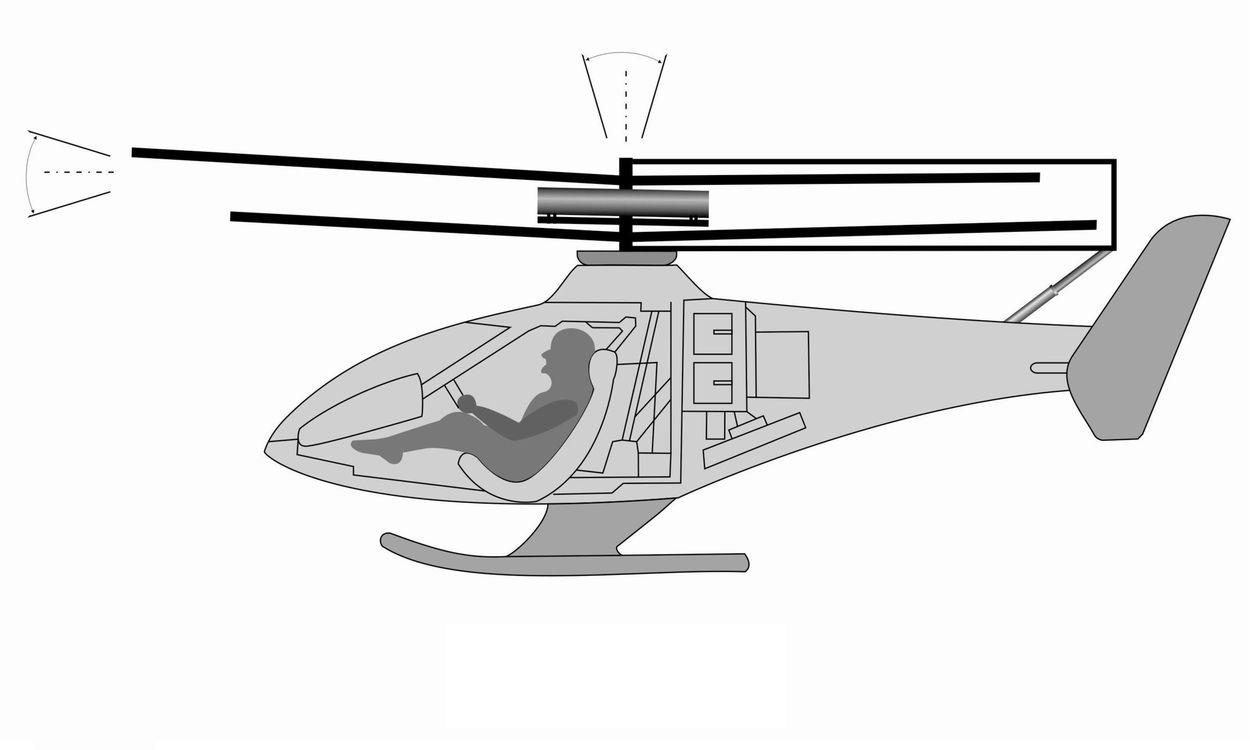

Individual helicopter (bi-rotative)

The scheme №5

Aerocycle with bi-rotative engine

The disk-shaped drive (bi-rotative) designed by us allows, to

design flight vehicles on a coaxial scheme without

application of the main reduction gearbox and a column of rotors with very

rigid, short enough blades hard-mounted on the bush.

The

rotation of two diverse on an altitude propellers in

the opposite sides and the sync of rotation is

provided with the drive (bi-rotative). The engine

installation on the basis of the created drive (bi-rotative) allows to dispose propellers in

shaft , that essentially improves safety a flight vehicle and dilates

sphere of its application

Flight vehicles

created on the basis of the designed drive (bi-rotative) are very prime in manufacturing and

rather not expensive.

The helicopter lay-out dual-rotor, coaxial. Selection

of the scheme: without application of the main-rotor gearbox and a column it is

justified by the following reasons:

Profitability. It

is stipulated not only absence of losses on the main-rotor gearbox and the

drive of a tail rotor, but also by higher efficiency of a system of two close

located opposite rotating coaxial propellers. For the same reasons, the coaxial

scheme supposes essentially the bigger loading per unit of power of an engine,

or ensures the bigger thrust\weight ratio both static and dynamic ceilings at

equal loading on power.

Maneuverability. It

is caused by absence at fulfilment of accelerated

turns of the limitations connected to hit of a tail rotor in a condition of a

vortex ring and limitations, overlapped on a condition of strength of a tail

boom. Besides the coaxial-rotor helicopter has smaller longitudinal and travelling moments of inertia in 1,5...2

times.

Leading

dimensions. The coaxial scheme is more compact to

diameter than rotors and on length.

Safety of flight. It

is caused by activity of propellers in a ring (shaft) and the absence of a

tail rotor with which, according to a statistician, the majority of flight incidents (breakage of a

propeller and its drive, graze for an obstruction, hit of

people in a rotating propeller on the land) is connected. On the safety of

flight also (through fatigue of the pilot) the absence of the vibrations

influences, that is the characteristic for coaxial-rotor helicopters with rigid

propellers. Application of

the scheme "a propeller

in a ring" enables to equip flight vehicles with a parachute

system of saving.

Quality of

control. It is caused by an aerodynamic symmetry

of the coaxial helicopter. Reaction torques from opposite

rotating propellers are mutually counterbalanced. Gyroscopic torques of

propellers are equal on value, are opposite directed and do not influence on a

piloting. Behaviour of the helicopter during manoeuvring, as against the single-rotor, predicted and

equal to the right and left sides. Cross couplings practically are absent.

Intensive turns do not influence on the changing of the altitude and do not

call changes of operational mode of the engine. All this makes control of the

helicopter simple and unfatiguing even for pilots of

mean and low qualification. Absence of the vibration by activity of rigid

propellers improves operating conditions of the board

avionics, stimulates a heightening of resource of a glider and other

aggregates which longevity depends on the parameters of vibrations.

A noise level.

Researches display; that exactly the coaxial scheme has the greatest

perspectives of lowering of the level of a sound pressure that is connected to

three factors. First, there is no such source of high-frequency acoustical

noise as a tail rotor and the main-rotor gearbox. Second, the coaxial carrier system

with rigid propellers as contrasted to an equivalent single carrier propeller rustles

less. Thirdly, at a pine to the scheme there is a capability of lowering of a

peripheral velocity of roter blades. Thus not only

noise is essentially reduced, but also wave losses decrease at the flight on

the extreme high speeds. Absence of the drive of a tail rotor and application

of rigid propellers

are capable to solve cardinally a problem of the noise of the

helicopter and which most likely, will find application on the special

noiseless machines. It will not demand of the special realization, enough labour-consuming researches.

The designed engine, allows to

design flight vehicles from superlight (pilotless and remotely manned)

up to light (from 1 - 6 person) with obtaining tall flying-engineering,

economic and operating performances in view of demands of minimization of the

time and financial expenditures of creation and start in the series production.

Besides heightening of the flying -technical datas,

our invention is directed on the cost reduction both on manufacture, and on

maintenance, that will increase competitive strength of the given concept of a

flight vehicle.

Thus, the

disk-shaped rotor-piston, the two-cycle engine created on the basis of a new

system of an energy transfer of gases in mechanical energy, has the following

essential advantages:

- Metal consumption, as a minimum in a three times is

reduced

- The absence of the vibration

- An easy running

- The uniform torque

- The simplicity of a construction:

р) The system of lubrication based

on application of rolling-contact bearings

b)

Application of the existing analogue, commercial machines of pistons and

cylinders

c) The

installation on the unit from 2 up to 12 cylinders, for the increasing of power

does not demand from the desing changes

of the

engine

d) At

the increasing of power of an engine, the mass is augmented only by weight of

the cylinder, the piston and the thruster

e)

Absence of a flywheel; a cylinder block executes it

- Application of the rolling-contact bearings allows

to lower coefficient of friction to a minimum and to increase the service life

of a drive

- By the cause of rotation

of a cylinder block and centrifugal forces, there is a stratification of a

fuel-air charge in the cylinder and

the displacement of an enriched charge in to the region of a spark plug, that ensures an effective work

on lean fuel

- Structural

features of a drive allow to achieve maximum power

from the unit of the

volume and minimum weight per one horsepower

- The capability cardinally to reduce a noise level

- The construction allows to have two power shafts and

to ensure automatically synchronization

of them, of the rotation in a different direction

The

application of the disk-shaped rotor-piston, a two-cycle engine with the

rotated cylinder

block (bi-rotative) in the helicopter

building industry, allows to design and manufacture easy flight vehicles under the coaxial scheme without application of the

main-rotor gearbox, a column and the control propeller.

Such

engine (bi-rotative) for a flight

vehicle helps to resolve such problems as:

- Weight of a

flight vehicle

- Simplicity and

reliability of a construction of a flight vehicle, in connection with absence

such difficult gears as the main-rotor

gearbox, a column, a tail transmission and a propeller

- It is

essentially reduced leading dimensions of a flight vehicle, determined from the

diameter of rotors

- Compactness of a

construction

- The capability

completely solve the problem of a noise level

- Manoeuvrability of a flight vehicle

- Safety of a

flight vehicle is reached by arrangement of propellers in part or completely in a guarded plane

- Quality and the

simplicity of control

- The application

of the scheme "a propeller in a ring" allows to equip flight vehicles with the

parachute system of saving.

Now, the development of our firm have passed stage of licensing in Russia,

on a engine the patent is obtainted, and on the power

installation and its application the

requests are sent in the patent department of Russia.

The firm "Global Energy Systems" addresses to you with the proposal to

discuss the capability and the expediency of using of our perspective

development in the field of an engine building and aircraft manufacturing with

the further start in series production and its movement on the consumer market.

We invite You for cooperation.

Frequently asked

questions.

.

1. To

what type of the products your

proposal is directed?

Answer:

Our offer is directed to a manufacture of the engines

of a new generation for the VTOL (vertical

take-off and landing) aircrafts.

2. To what market your

proposal is directed?

Answer:

Our offer is directed to the market of light, super

light and pilotless VTOL (vertical take-off

and landing) aircrafts, and also to the other types of VTOL aircrafts .

3. What

now exists in the market, and is similar to your proposal?

Answer:

Now at the market exist basically light one-screw and super light

aircrafts:

Manufacturers and developers:

1.

2. Revolution

Helicopters,

3. Dragon Fly s.r.l.,

4. A-B

Helicopters,

5. JAG

Helicopters Group (Rinke Aerospace),

6. Eagle

R&D,

7. Canadian

Home Rotors Int.,

8. Rotorway International,

9. Robinson

Helicopter Company,

10.

11.Novacopter Inc. Ltd,

These manufacturers are developing and manufacturing one-screw aircrafts, and only such manufacturers as:

1.

2. Eagle's perch Inc,

are engaged in

the development and manufacturing of the twin-propeller aircrafts with the

coaxial scheme which are a partial similarity of our invention.

4. How your proposal is better

than something, what now exists?

Answer:

Our offer to cooperation on

development and creation of aircrafts on the basis of power installation

located between screws the engine, what allows to refuse

from the application of such difficult units and parts as:

1.

The main reducer

2.

Column

3. Automatic

devices of skewing and of the tail propeller.

According

to this the reliability and the payload of the aircraft increases.

5. Please provide a list of all applications, patents,

recordings, etc. touching protection of any intellectual property covering your

proposal. Please, describe

type of protection (the patent, the design, etc.), the production numbers,

specify, whether is all this on viewing, or it has

been authorized, and the country of recording?

Answer:

It is applied in:

1. Pilotless

VTOL (vertical take-off and landing)

aircrafts.

2. Super

easy VTOL (vertical take-off and landing)

aircrafts.

3. Easy VTOL (vertical take-off and landing) aircrafts.

4. Flying VTOL (vertical take-off and landing) platforms.

And also it can be used as the

engine in different types machines,

especially in vehicles.

Type of protection:

1. The patent "The rotor-reciprocating

internal-combustion engine with air

cooling" № 2151313 from the 01.10.1999,

2. The application for the reception of the patent "The

helicopter of the coaxial scheme with an arrangement of the engine

between screws" № 2005113204 from the 03.05.2005,

6. Do you want to present the

proposal from you? Define yours degree of participation and/or do you want us

to sell to you the proposal, and etc.?

Answer:

We assume the sale of the given

invention and the further joint participation in its improvement with

the rendering of the technical, consulting and any other help, with the promotion

of finished articles in various regions of the world.

Also we shall consider the proposals about possible creation of joint

design office for adaptation and starting of the series production of the given

engine (bi-rotative).

Yours faithfully,

Deputy of General Director V. Tchernov

Chief

designer A. Anishchenko

The full

version in a format .doc -839kb

Videoа material is in the "QuickTime

Movie"а format

The Player you can download here:

Or VLC player from here:

http://www.videolan.org/vlc/download-windows.html

-20,1 Mb

Links to download Videos:

Videoclip

№1 - Rise - - 2,11 Mb

Videoclip №2 - The

second propeller - - 4,95 Mb

Videoclip №3 - The

first sample - - 2,57 Mb

Videoclip

№4 - Work - -1,49

Mb

Videoclip №5 - Stop - -1,77 Mb

Videoclip

№6 - 3D bi-rotative engine - - 667 Kb

Our

contacts:

Global Energy Systems Ltd.

Deputy of General Director Tel: +7 985 150 05 30

General Designer Tel: +7 928 314 01 73

e-mail: pochta2660@gmail.com